Call 24/7 to

+31 70 319 24 00

service@geerlofs.nl

More about our service?

- Home

- About us

- References

- News

- Markets

- Products

- Service

- Contact

The storage of potatoes and onions is a difficult task. These are root vegetables and obviously grown underground. Mechanical harvesting often damages potatoes, because they are taken out of the ground with some ‘violence’. And that is not the end: both onions and potatoes are often very wet upon gathering.

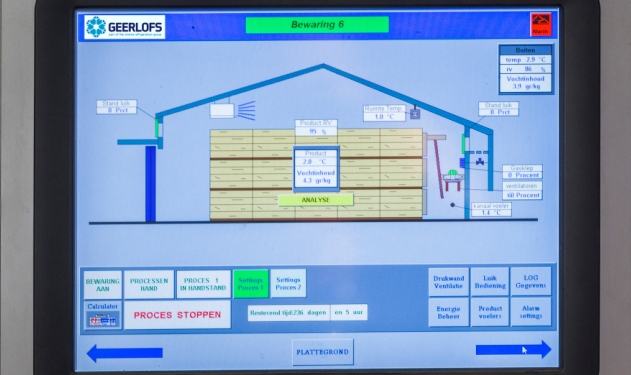

First of all we choose the storage technique depending on your wishes: in boxes or bulk. In the first case we ventilate using a pressure wall. And for this second option we choose the type of ventilation: with half round or underground channels.

Due to the moisture and damage, a proper storage consists of three phases: drying, cooling down, storage. During the drying process the wound healing of the potatoes also takes place: the wounds are covered with new skin. The drying process is a clever combination of ventilation with outside air and possible heating with heaters or mechanical cooling. After drying, the crop is slowly being cooled down to storage temperature. This may take several days. As soon as the storage temperature is reached, this level should be maintained as closely as possible as to reduce dehydration to a minimum. Apart from that, dehydration is also avoided by creating only a tiny difference between the evaporation and room temperatures. The process of dehydration is countered by enlarging the cooling surface of the evaporator. As the evaporators become bigger they are also more expensive, but in return you will retain more kilos in your potato and onion storage.

Due to the long-standing cooperation with leading Dutch potato and onion breeders, Geerlofs has been able to automate the three phases in the Gispro® technique. This technique controls the ventilation hatches and the mechanical cooling in such a way that the fresh produce keeps it freshness longer and losses less moisture. Because of this, the breeder achieves ‘value for money’: maximum amount of good quality fresh produce at the end of the storage period.

What is more, we are able to do this for minimum costs by saving energy in a sustainable way. We dry and cool with fresh air as much as possible. Needless to say, Geerlofs Refrigeration knows how to make mechanical cooling efficient like no one else. And we prefer to use natural refrigerants, of course.

For over 80 years, Geerlofs has been a specialist in agricultural cooling on national and international level with your colleagues: