Call 24/7 to

+31 70 319 24 00

service@geerlofs.nl

More about our service?

- Home

- About us

- References

- News

- Markets

- Products

- Service

- Contact

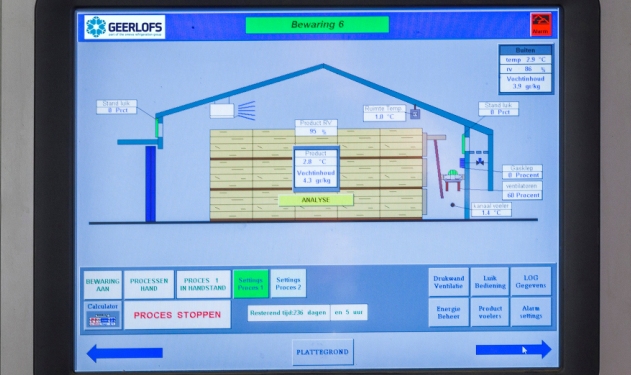

For the storage and processing of fresh goods we rely on ventilation technology (adding fresh air) for several reasons: discharging of the generated CO2 and ethylene, especially with fruits, oxygen supply for staff making long shifts in the processing hall, and the most extensive application: drying tubers such as onions and potatoes.

For mechanical harvesting, which might damage the produce, and/or harvesting wet goods, ventilation is necessary to enable wound healing and drying. Next to that, fresh air can also be used for cooling, also known as ‘free cooling’ as one relies on freely available cooling capacity.

Fresh produce breathes and therefore produces CO2. Some fruits produce ethylene as part of the aging/rotting process. A minimal amount of fresh air is needed to discharge these gasses.

There is a guideline for the amount of necessary oxygen for working staff. A ventilation system should meet these requirements. If it fails to do so, people will suffer from headaches or get droopy.